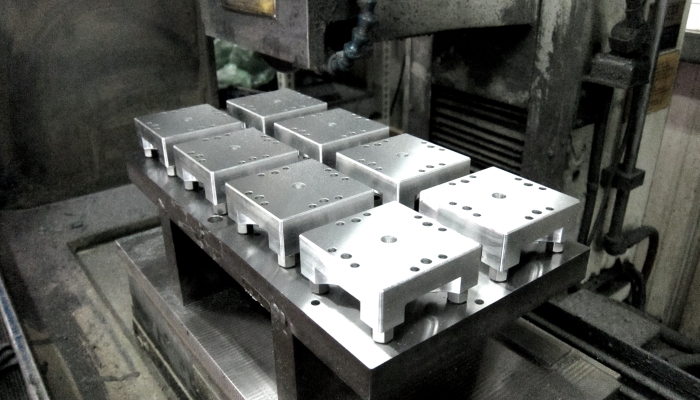

Grinding

A grinding machine is used to finish precision CNC machining components that must be featured with high surface quality (e.g., low surface roughness) and high accuracy of shape and dimension.

The size, shape, features and desired production rate of workpieces are to determine which of the following grinding operations to be used in Apporo.

Surface grinding

The surface grinding machine is equipped with 3-axis automatic movement with incremental downfeed, electronic auto-crossfeed, and proportional valve hydraulic powered table movement. Consider that the inquiry for highly flatness and also good surface roughness, we would like to use this machine to produce a smooth accurate finish on either metal or non-metal flat surface. The surface material are to be removed by the application of abrasives which are bonded to form a rotating wheel. When the moving abrasive particles contact the workpiece, they act as tiny cutting tools, each particle cutting a tiny chip from the workpiece.

Outside Diameter Grinding

Outside diameter(OD) grinding is to grind the external surface of the workpiece between two centers. The two centers are to touch at both end of the workpiece and rotate. Cylindrical OD grinding is ideal for parts with single or multiple diameters that need to run concentric with each other or between centers.

Infeed Grinding

As for infeed grinding, there is no need for collet or centers to hold the workpiece in place when compare to OD grinding. We use an adjusting wheel positioned on the opposite side of the object to the grinding wheel to redulate the axial movement of the workpiece. Frankly speaking, centerless grinding is much easier to combine with automatic loading procedures than OD grinding.

Through Feed Grinding

Through feed grinding is for applications where only the largest outside diameter is to be ground. The regulating wheel is held at a slight angle to the part. So that, there is a force feeding the part through the grinder. Actually, centerless grinding is much easier and more efficient way to run with an automatic loading equipment than centered grinding.